Concrete Cover Blocks: Enhancing the Durability of Concrete Structures

Introduction to Concrete Cover Blocks:

In construction, meticulous planning and attention to detail are essential to ensure the longevity and durability of any structure. One such crucial component that plays a significant role in safeguarding concrete structures is the “Concrete Cover Block.” These small but indispensable elements act as spacers, maintaining a specified distance between the reinforcement steel bars and the outer surfaces of the concrete. In this article, we delve into the importance of concrete cover blocks, their types, installation methods, compliance with codes, benefits, challenges, sustainable alternatives, and innovations in this realm.

The Necessity of Concrete Cover Blocks:

Concrete Quality and Durability:

Concrete cover blocks play a pivotal role in achieving better concrete quality and durability. By maintaining the specified distance between the reinforcement and the concrete surface, they ensure that the concrete adequately covers and surrounds the steel bars. This covering enhances the bond between the reinforcement and the concrete, resulting in a robust and long-lasting structure.

Protection against Corrosion:

One of the primary reasons for the premature failure of concrete structures is the corrosion of reinforcement steel. Cover blocks act as a barrier, preventing moisture, chloride ions, and other corrosive elements from reaching the steel. This protection significantly increases the service life of the structure, especially in coastal or aggressive environments.

Fire Resistance:

Adequate concrete cover provided by the cover blocks offers a certain degree of fire resistance to the reinforcement. In the event of a fire, the concrete cover acts as an insulating layer, protecting the steel bars from reaching critical temperatures and maintaining the structural stability.

Bond Strength:

Properly spaced cover blocks ensure that the concrete can flow around the reinforcement, providing a strong bond between the two materials. This bond strength enhances the load-carrying capacity of the structure and prevents the steel bars from slipping or detaching during loading.

Preventing Reinforcement Congestion:

In heavily reinforced sections, such as columns or beams, it is essential to maintain proper spacing between the steel bars. Cover blocks help prevent congestion of reinforcement, which can lead to improper compaction and weak zones in the concrete.

Dimensional Accuracy:

Cover blocks assist in achieving the specified dimensions and shape of concrete elements. They act as a formwork guide during concrete placement, ensuring uniform concrete thickness and accurate dimensions.

Easy Inspection:

Adequate concrete cover allows for easy visual inspection of the reinforcement during construction and throughout the service life of the structure. It facilitates the detection of any signs of corrosion, damage, or defects, enabling timely maintenance and repairs.

Types of Concrete Cover Blocks:

Concrete cover blocks come in various shapes and materials, each catering to specific construction requirements. Some common types include:

Plastic Cover Blocks:

Plastic cover blocks are lightweight and easy to handle. They are available in various sizes and shapes, making them versatile for different applications. The use of plastic cover blocks helps reduce the overall weight of the structure, making it suitable for high-rise buildings.

Fiber-Reinforced Concrete Cover Blocks:

Fiber-reinforced concrete cover blocks offer enhanced tensile strength and durability. The incorporation of fibers in the concrete mix provides additional reinforcement, reducing the risk of cracking and improving the structural resilience.

Spacer Blocks in Construction:

spacer

These blocks are widely used in precast concrete elements. They ensure consistent spacing between the reinforcement and the concrete surface, allowing for uniform concrete cover.

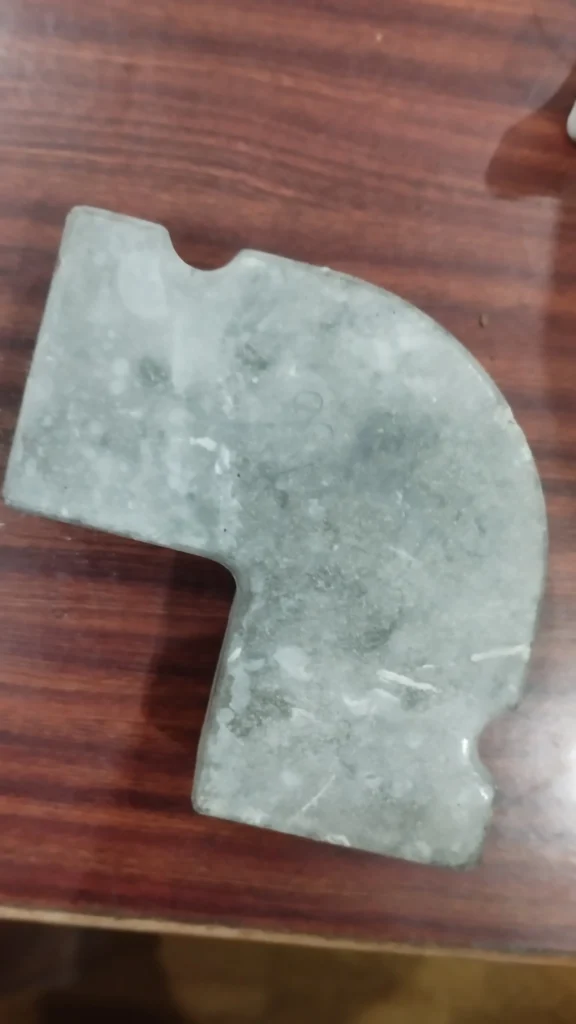

Circular Cover Blocks:

Circular cover blocks are specifically designed to provide cover to circular or curved elements such as pipes and columns. Their shape ensures a seamless fit around these structures.

Mesh Cover Blocks:

Mesh cover blocks consist of a grid-like structure, offering support and cover to a large area of reinforcement. They are commonly used in heavily reinforced sections.

Installation of Concrete Cover Blocks:

Proper installation of concrete cover blocks is crucial to ensure their effectiveness in protecting the reinforcement. Some key considerations during installation are

Spacing and Positioning:

The spacing between cover blocks should comply with the relevant building codes and design specifications. Proper positioning of cover blocks is essential to achieve uniform concrete cover throughout the structure.

Support and Fixing Methods:

Cover blocks should be firmly supported and fixed in place during concrete pouring. Adequate support ensures that the cover blocks remain in their intended position and do not shift during construction.

Cover Blocks for Different Structural Elements:

Different structural elements may require varying types and sizes of cover blocks. The installation process must account for the specific requirements of each element, such as beams, slabs, columns, and walls.

Importance of Compliance with Codes and Standards:

Adherence to international and national building codes and standards is critical when using concrete cover blocks. These codes outline the minimum required cover thickness, quality standards, and other essential guidelines to ensure structural safety and durability.

Common Mistakes and Challenges in Using Cover Blocks:

Despite their importance, the improper use of concrete cover blocks can lead to various challenges, including

Inadequate Cover Thickness:

Insufficient concrete cover can compromise the reinforcement’s protection against corrosion and reduce the structural integrity of the concrete element.

Improper Installation:

Incorrect installation of cover blocks can result in misaligned reinforcement, reduced bond strength, and compromised structural stability.

Concrete Cover in Aggressive Environments:

In aggressive environments with high exposure to moisture, chemicals, or saltwater, using the wrong type of cover block can accelerate corrosion and shorten the structure’s lifespan.

Benefits of Using Concrete Cover Blocks:

The utilization of concrete cover blocks brings numerous advantages, including:

Increased Structural Integrity:

Concrete cover blocks enhance the bond between the reinforcement and the concrete, resulting in a structurally sound and stable building.

Extended Service Life of Structures:

Effective use of cover blocks significantly reduces the risk of corrosion, extending the service life of concrete structures.

Cost-Effectiveness:

The relatively low cost of cover blocks compared to potential repairs or replacements makes them a cost-effective investment in the long run.

Improved Safety and Security:

Structures with proper concrete cover have improved resistance to fire and other hazards, ensuring the safety of occupants and valuable assets.

Sustainable Alternatives to Traditional Cover Blocks:

As sustainability gains momentum in the construction industry, various eco-friendly alternatives to traditional cover blocks have emerged, including:

Eco-Friendly Materials:

Some cover blocks are made from recycled materials or eco-friendly substances, reducing their environmental impact.

Recycled Cover Blocks:

Cover blocks made from recycled concrete or other materials contribute to waste reduction and resource conservation.

Innovations in Concrete Cover Blocks:

Self-Healing Cover Blocks:

Self-healing cover blocks contain special additives that can automatically repair cracks, enhancing the durability of the concrete element.

Smart Cover Blocks with Sensors:

Cover blocks embedded with sensors can monitor environmental conditions, corrosion levels, and structural integrity, providing valuable data for maintenance and performance assessment.

Best Practices for Proper Concrete Cover Block Usage:

Quality Control and Testing:

Regular quality control measures and testing ensure that the cover blocks meet the required standards and performance criteria.

Regular Maintenance and Inspection:

Scheduled inspections and maintenance of the concrete cover blocks and the overall structure help detect issues early and prevent costly damages.

Conclusion:

Concrete cover blocks are a critical component in the construction industry, offering significant benefits in terms of structural integrity, safety, and durability. Their proper use, installation, and compliance with building codes ensure that concrete structures stand the test of time, even in harsh environments. As innovations continue to shape the construction landscape, sustainable and smart cover block solutions pave the way for a greener and more resilient future.

FAQs (Frequently Asked Questions):

1. How do concrete cover blocks protect reinforcement from corrosion? Concrete cover blocks act as a protective barrier, preventing corrosive agents from reaching the reinforcement steel, thereby extending the structure’s service life.

2. Can I use plastic cover blocks for high-rise buildings? Yes, plastic cover blocks are suitable for high-rise buildings due to their lightweight properties and ease of handling.

3. What are some sustainable alternatives to traditional concrete cover blocks? Eco-friendly materials and recycled cover blocks are sustainable alternatives that reduce environmental impact.

4. Are smart cover blocks with sensors widely available in the market? While the technology is still emerging, smart cover blocks with embedded sensors are becoming more accessible to the construction industry.

5. How often should I inspect and maintain concrete cover blocks? Regular inspections and maintenance should be conducted as part of routine building maintenance, ideally at least once a year.